Get more information about electronics manufacturing solutions for modern production

Startling misconceptions surround electronics manufacturing, often portraying it as a cumbersome, outdated industry struggling to keep pace with technological advancements. However, modern production solutions have significantly transformed this perception, seamlessly integrating cutting-edge technologies with traditional manufacturing processes.

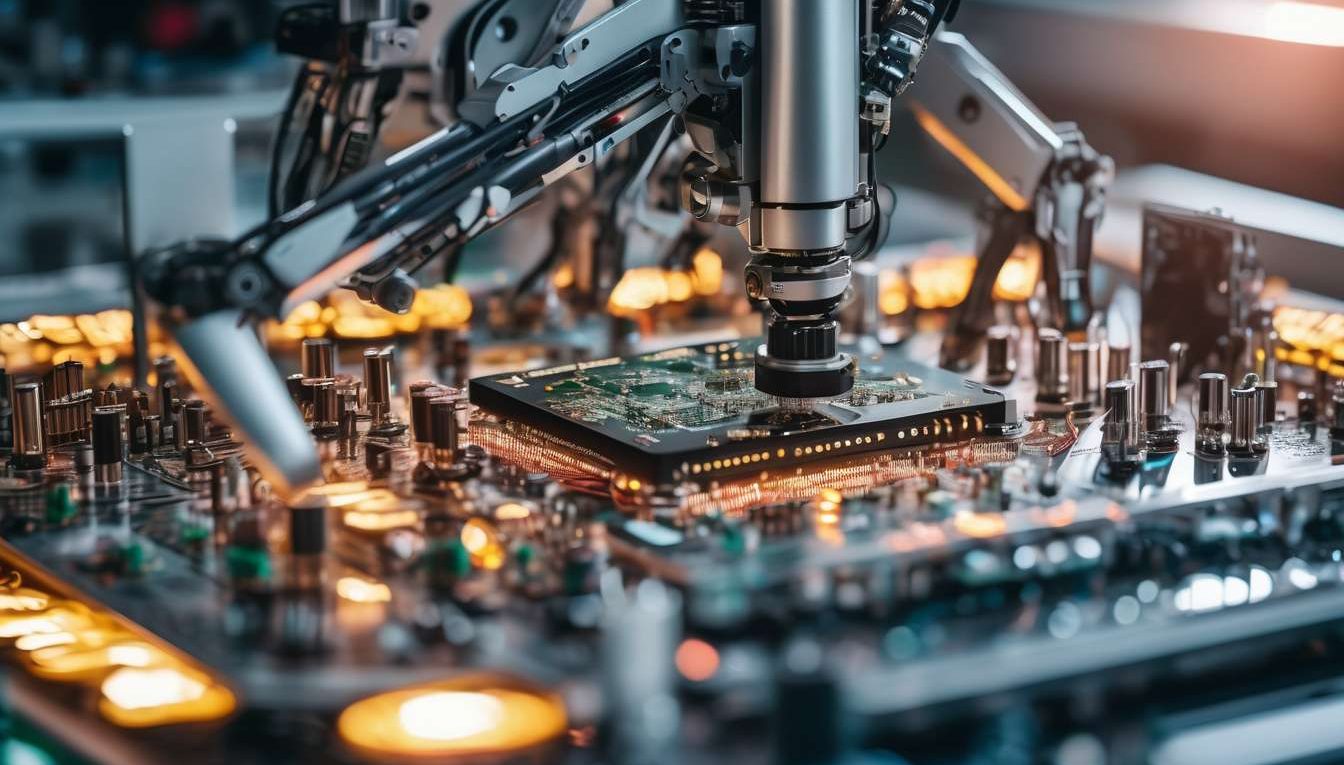

This sector, crucial to numerous industries, has evolved into a hub of innovation, efficiency, and precision, driving the global economy forward. Robotics, automation, and advanced materials are reshaping how electronic components are designed, produced, and delivered.

Key advancements include:

- The integration of Internet of Things (IoT) technologies

- The application of artificial intelligence to enhance production capabilities

These advancements enable manufacturers to meet the growing demand for smarter, more efficient devices. As companies seek to improve product quality and reduce time-to-market, embracing these advancements becomes indispensable.

Exploring the array of contemporary solutions available reveals an industry not only ready for the digital age but thriving within it. Understanding these innovations is essential for stakeholders aiming to leverage modern manufacturing capabilities to their advantage.

To delve deeper into how these innovations are revolutionizing electronics manufacturing, this link will take you further.

IoT Integration in Manufacturing

Integrating IoT into Manufacturing

Integrating IoT into manufacturing processes significantly enhances operational efficiency and real-time data monitoring. By leveraging IoT, manufacturers can:

- Automate and streamline operations

- Reduce manual intervention

- Minimize errors

The interconnected network of IoT devices facilitates seamless communication and coordination among machinery, fostering a cohesive production environment. This integration allows for accurate data collection and analysis, enabling informed decision-making and proactive maintenance.

Benefits of IoT Integration

- Reduced operational downtime

- Increased productivity

- Cost savings

Synergy between IoT, AI, and Robotics

The synergy between IoT, AI, and robotics revolutionizes manufacturing by creating smart factories. Key components include:

-

Data Collection and Analysis: IoT devices collect vast amounts of data, which AI algorithms analyze to optimize production processes.

-

Enhanced Ecosystem with Robotics: Robotics perform repetitive tasks with precision and speed, improving product quality and consistency.

The combination of these technologies cultivates an environment where manufacturers can innovate and adapt quickly to market demands, ensuring their position in a competitive landscape.

Community and Innovation

This integration fosters a sense of belonging within a forward-thinking community, positioning manufacturers to thrive in an evolving industry.

AI Applications for Production Enhancement

Leveraging advanced algorithms and machine learning models, manufacturers can enhance production processes by:

- Predicting maintenance needs

- Optimizing resource allocation

Integrating AI into manufacturing operations enables:

- Real-time data analysis

- Proactive decision-making

- Reduced downtime

By harnessing the vast potential of IoT, interconnected devices can:

- Gather and transmit data

- Offer insights into equipment performance

- Monitor energy consumption

This further streamlines operations.

AI-driven analytics provide a competitive edge by:

- Identifying bottlenecks in production lines

- Suggesting improvements

This capability extends to supply chain management, where AI can:

- Forecast demand

- Adjust inventory levels accordingly

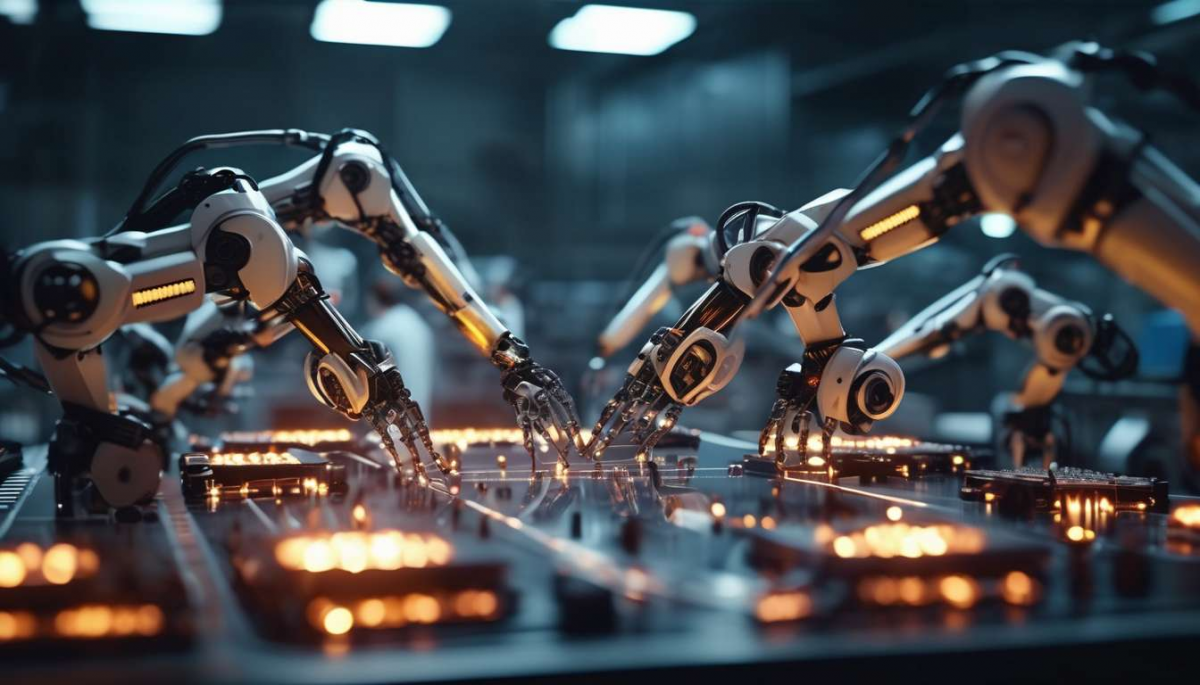

Robotics, powered by AI, further enhance precision and efficiency by:

- Executing repetitive tasks with minimal error

- Freeing up human resources for more complex duties

The synergy between AI, IoT, and Robotics is transforming traditional manufacturing into a smart, interconnected ecosystem.

This transformation not only boosts productivity but also fosters a collaborative environment where technology and human ingenuity converge, paving the way for sustainable growth and innovation in the electronics manufacturing sector.

Robotics: Revolutionizing Assembly Lines

Cutting-edge robotic technologies are transforming assembly lines by increasing efficiency and precision while reducing human error. Robotics, integrated with Artificial Intelligence (AI) and the Internet of Things (IoT), offer robust solutions for modern electronics manufacturing. These technologies enhance production capabilities, ensuring assembly lines operate with greater accuracy and speed.

AI-driven robotics can perform complex tasks with minimal supervision, enabling manufacturers to maintain high-quality standards consistently.

IoT integration further enables real-time data exchange between machines, leading to optimized workflows and predictive maintenance. This results in reduced downtime, which is crucial for maintaining a competitive advantage in the fast-paced electronics market.

Robotics also facilitate flexibility in production lines, allowing for rapid adaptation to changing consumer demands and technological advancements.

By embracing these innovations, manufacturers can foster a sense of community among:

- Industry leaders

- Suppliers

- Customers

These stakeholders collectively benefit from the seamless and efficient production processes.

The synergy between robotics, AI, and IoT is reshaping the landscape of electronics manufacturing, driving progress and innovation.

Advanced Materials in Electronics Manufacturing

Incorporating advanced materials into electronics manufacturing significantly enhances device performance, durability, and efficiency. These materials, such as graphene, nanomaterials, and conductive polymers, are pivotal in advancing the capabilities of IoT devices, AI systems, and robotics.

Key Benefits of Advanced Materials:

- Superior electrical conductivity

- Thermal stability

- Mechanical strength

These characteristics are essential for modern electronic components.

The integration of such materials allows for the development of devices that are:

- Smaller

- Faster

- More energy-efficient

This integration meets the growing demands of interconnected technologies.

In IoT applications, advanced materials enable the creation of sensors with improved sensitivity and reliability. This facilitates seamless communication between devices.

AI systems benefit from enhanced processing power and energy efficiency provided by these materials, leading to faster data analysis and decision-making capabilities.

In robotics, the use of lightweight and durable materials improves the agility and lifespan of robotic components, enhancing both functionality and performance of automation solutions.

These advancements contribute to a more connected, intelligent, and efficient technological ecosystem, fostering growth and innovation within the industry.

Efficient Supply Chain Management Solutions

Efficient supply chain management solutions are crucial for optimizing production processes and ensuring timely delivery of electronic components.

The integration of IoT, AI, and Robotics into supply chain operations significantly enhances efficiency and accuracy.

IoT facilitates:

- Real-time tracking of inventory levels

- Monitoring shipment status

This promotes a seamless flow of materials and reduces the risk of delays.

AI-driven analytics provide insights into:

- Demand forecasting

- Inventory management

This enables manufacturers to anticipate market trends and adjust production schedules accordingly, ensuring that resources are allocated efficiently, minimizing waste, and maximizing productivity.

Robotics plays a pivotal role in:

- Automating repetitive tasks within the supply chain

- Increasing speed and precision

- Reducing human error, which is vital in maintaining the quality and consistency of electronic components

By leveraging these technologies, manufacturers can foster a collaborative environment where partners across the supply chain feel connected and informed.

This integration not only strengthens partnerships but also enhances the overall resilience and responsiveness of the supply chain.

Embracing Smart Manufacturing Technologies

Smart manufacturing technologies revolutionize electronics production by integrating advanced systems that enhance:

- Efficiency

- Precision

- Adaptability

Key technologies driving this transformation include IoT, AI, and robotics, enabling a seamless connection across various production stages.

IoT facilitates real-time data collection and analysis, ensuring effective communication across manufacturing components. This capability reduces downtime and optimizes resource allocation.

AI plays a crucial role in:

- Predictive maintenance

- Quality control

By allowing manufacturers to foresee potential issues and implement corrective actions proactively, AI minimizes production errors and ensures consistent quality in electronic products.

Robotics elevates automation by:

- Performing repetitive tasks with high precision

- Reducing human error

- Increasing throughput

By embracing these technologies, the manufacturing industry fosters a sense of community among stakeholders. Shared knowledge and resources contribute to collective growth.

The integration of IoT, AI, and robotics in manufacturing processes represents a significant step towards a more sustainable and competitive future.